Overview of the B6․4D Manual

The B6․4D manual provides a comprehensive guide for setting up and maintaining the RC10B6․4D model․ It includes detailed assembly instructions, compatibility tips, and troubleshooting solutions for optimal performance․

The B6․4D is a high-performance RC buggy designed for competitive racing and hobbyist use․ It belongs to Team Associated’s RC10 series, known for its durability and adaptability to various track conditions․ The model is optimized for indoor tracks but can also perform well outdoors with proper setup․ Its advanced design includes lightweight components, adjustable suspension, and a robust drivetrain, making it suitable for both beginners and experienced racers; The B6․4D manual is tailored to help users understand the model’s features, assembly, and maintenance, ensuring optimal performance and longevity․ It serves as a valuable resource for anyone looking to unlock the full potential of their RC10B6․4D buggy․

1․2 Purpose and Scope of the Manual

The purpose of the B6․4D manual is to provide users with a detailed guide for assembling, configuring, and maintaining the RC10B6․4D buggy․ It serves as a comprehensive resource for both novice and experienced racers, ensuring optimal performance and longevity of the model․ The manual covers essential topics such as step-by-step assembly instructions, initial setup tips, and troubleshooting common issues․ It also includes recommendations for regular maintenance and advanced tuning techniques․ The scope of the manual extends to addressing compatibility with various parts and accessories, helping users tailor their buggy to specific racing conditions․ By following the manual, users can unlock the full potential of their B6․4D, whether for casual racing or competitive events․

Key Features and Specifications

The B6;4D features durable materials, precision engineering, and compatibility with various upgrades․ Its advanced hardware and design ensure high performance, making it suitable for competitive racing environments․

2․1 Design and Build Quality

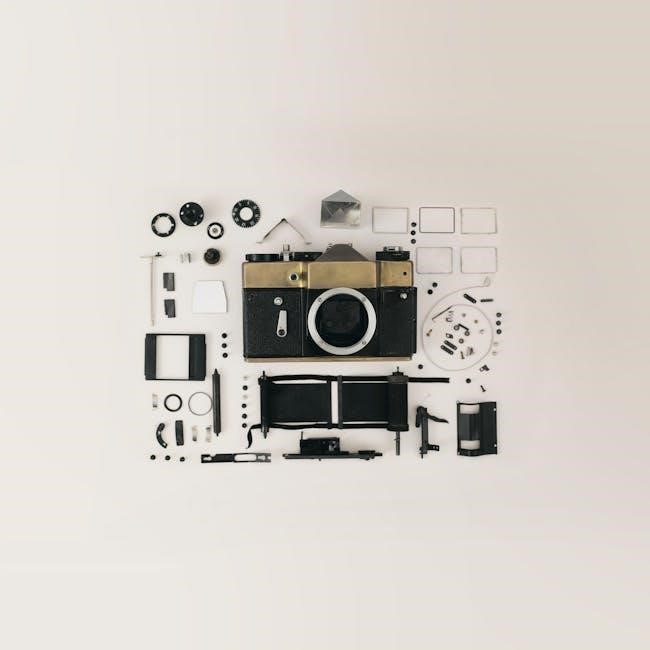

The B6․4D is crafted with premium materials, ensuring durability and lightweight performance․ Its chassis and components are precision-engineered for optimal strength and flexibility․ The model features a sleek, aerodynamic design that enhances stability and control during races․ Builders appreciate the high-quality hardware and clear assembly instructions, which simplify the setup process․ The manual includes a detailed hardware foldout page, allowing users to verify part sizes and ensure accuracy․ This attention to detail makes the B6․4D both reliable and competitive, catering to racers seeking a balance between performance and ease of use․

2․2 Technical Specifications and Compatibility

The B6․4D is compatible with a variety of components, including the Hobbywing 21․5 Justock ESC/motor combo, commonly used for indoor tracks․ It supports multiple setups, allowing customization to suit different racing conditions․ The manual emphasizes the importance of verifying part compatibility, especially when considering upgrades or modifications․ Users are advised to cross-reference the hardware foldout page to ensure accurate sizing and fitment․ This model is designed to work seamlessly with standard RC accessories, making it versatile for both novice and experienced racers․ Compatibility checks are crucial to maintain optimal performance and avoid potential issues during assembly or operation․

Assembly and Setup Guidance

The B6․4D manual offers step-by-step assembly instructions, ensuring proper hardware alignment and configuration․ It recommends using the foldout page to verify part sizes and compatibility for a smooth setup process․

3․1 Step-by-Step Assembly Instructions

The B6․4D manual provides a detailed, step-by-step guide for assembling the RC10B6․4D․ It begins with unpacking and inventorying parts, ensuring all components are accounted for․ The instructions then proceed to the chassis assembly, including the installation of the drivetrain, suspension, and steering components․ Each step is accompanied by clear diagrams and torque specifications to ensure proper alignment and security․ The manual emphasizes the importance of aligning hardware with the foldout page to verify part sizes and compatibility․ Additional guidance is provided for adjusting caster inserts and other setup-specific details to achieve the desired handling characteristics․ By following these instructions, users can confidently assemble their B6․4D for optimal performance and reliability․

3․2 Initial Setup and Configuration Tips

The B6․4D manual offers essential tips for initial setup and configuration to ensure optimal performance․ It recommends starting with the stock setup, using the provided 5 caster inserts for a balanced feel․ Users are advised to verify part sizes by aligning hardware with the foldout page in the manual․ Basic configurations, such as gear mesh adjustment and ride height settings, are detailed to ensure smooth operation․ The manual also provides guidance on suspension setup, emphasizing proper preload and damping adjustments․ Additionally, it includes torque specifications for key components to prevent overtightening․ By following these tips, users can achieve a well-configured B6․4D ready for racing or casual driving․ The manual’s clear instructions help avoid common setup mistakes, ensuring a seamless initial configuration process․

Maintenance and Troubleshooting

The B6․4D manual highlights common issues like gear mesh problems and loose screws, offering solutions such as adjustments and part replacements․ Regular cleaning and lubrication of moving parts are recommended to ensure smooth operation and prevent wear․ Users are advised to check for worn components and tighten fasteners periodically․ Proper torque specifications are provided to avoid over-tightening, which can damage the chassis or suspension․ Troubleshooting tips help identify and resolve issues quickly, keeping the model in optimal condition for racing or casual use․ Regular maintenance practices ensure longevity and performance of the B6․4D․

4․1 Common Issues and Solutions

Common issues with the B6․4D include gear mesh problems, loose screws, and compatibility conflicts with aftermarket parts․ Gear mesh issues can be resolved by adjusting the motor position and ensuring proper spacing․ Loose screws should be checked and tightened periodically using the recommended torque specifications․ Compatibility problems can be avoided by verifying part numbers and cross-referencing with the manual․ Users may also encounter electrical connectivity issues, which can be fixed by cleaning contacts and ensuring secure wire connections․ For worn or damaged parts, replacement is recommended to maintain performance․ The manual provides detailed diagrams to help identify and address these issues effectively․ Regular maintenance and inspections can prevent many of these problems from arising․

4․2 Regular Maintenance Practices

Regular maintenance is crucial for ensuring the longevity and performance of the B6․4D․ Users should periodically inspect and tighten all screws, especially after initial assembly, to prevent loosening during use․ Bearings and differential components should be cleaned and lubricated according to the manual’s specifications․ It is also important to check for wear on parts such as gears, shocks, and suspension components, replacing them as needed․ Cleaning the chassis and electrical components regularly can prevent dirt buildup and electrical issues․ Lubricating moving parts and ensuring proper alignment will maintain smooth operation․ Following these practices helps prevent common issues and ensures the model runs at its best․ Consistency in maintenance is key to extending the life of the B6․4D․

Advanced Tuning and Upgrades

Explore expert techniques for optimizing performance, including suspension adjustments, gear ratio tweaks, and upgrade recommendations for enhanced speed and handling on the B6․4D model․

5․1 Performance Optimization Techniques

Optimizing the B6․4D’s performance involves fine-tuning its suspension, adjusting gear ratios, and experimenting with different tire compounds․ Start by ensuring proper ride height and camber settings to maximize traction․ Next, consider upgrading to lightweight components such as aluminum or carbon fiber parts to reduce weight and improve handling; Adjusting the differential oils and shock absorbers can also significantly impact performance․ For advanced users, modifying the chassis flex by using different stiffness inserts can enhance cornering stability․ Additionally, experimenting with various motor and ESC combinations can unlock higher speeds and better acceleration․ Regularly testing and adjusting these settings on different track conditions will help achieve optimal performance․

5․2 Recommended Upgrades and Modifications

Upgrading the B6․4D can enhance its performance and adaptability to different racing conditions․ Consider replacing stock parts with lightweight aluminum components, such as chassis braces or steering racks, to reduce overall weight while maintaining durability․ High-torque servos and adjustable shock absorbers are also recommended for better control and stability․ Additionally, swapping the stock tires for specialized compounds can improve grip on various surfaces․ For advanced users, modifying the motor and ESC combination can unlock higher speeds and smoother acceleration․ Always ensure compatibility with Team Associated’s official parts list to maintain optimal functionality․ Testing each upgrade on the track will help refine the setup to suit your driving style and track conditions․